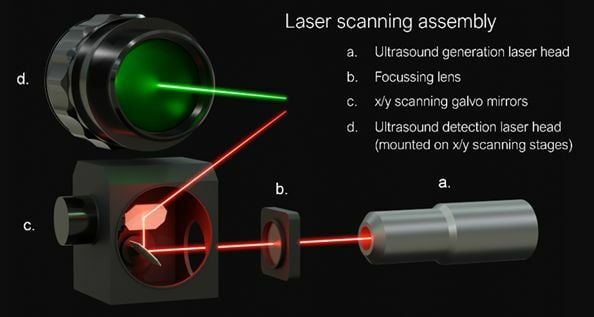

A diagram showing how LIPA works

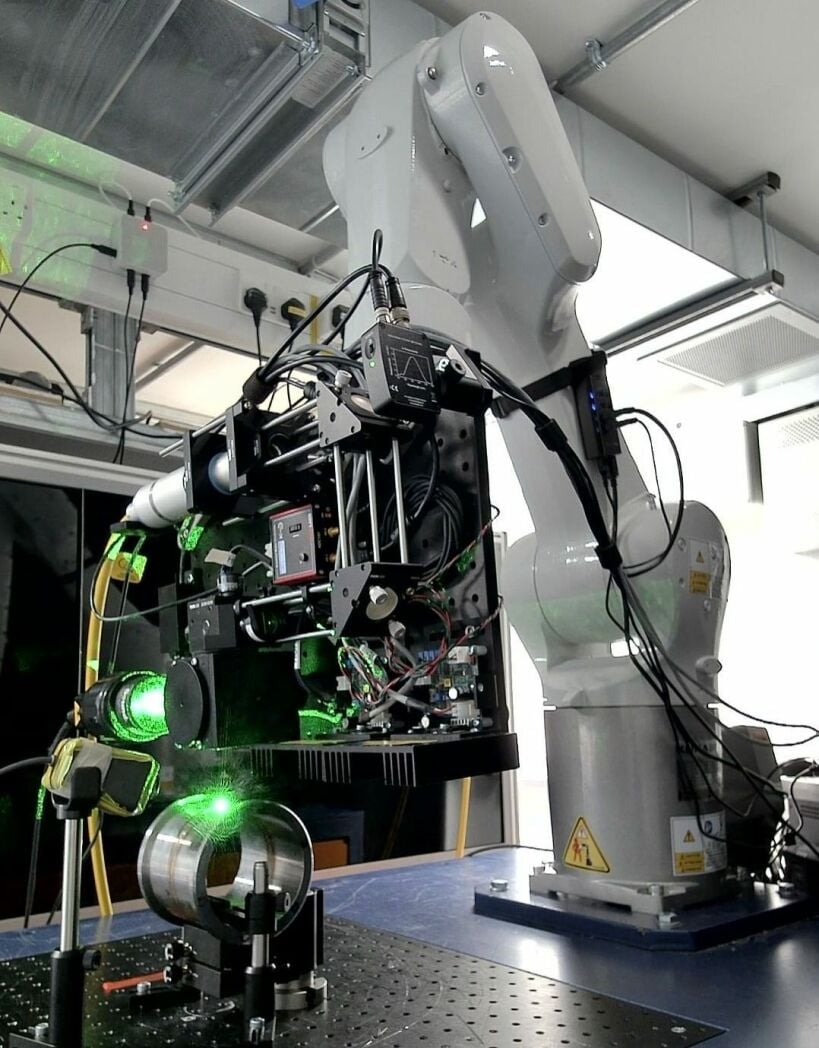

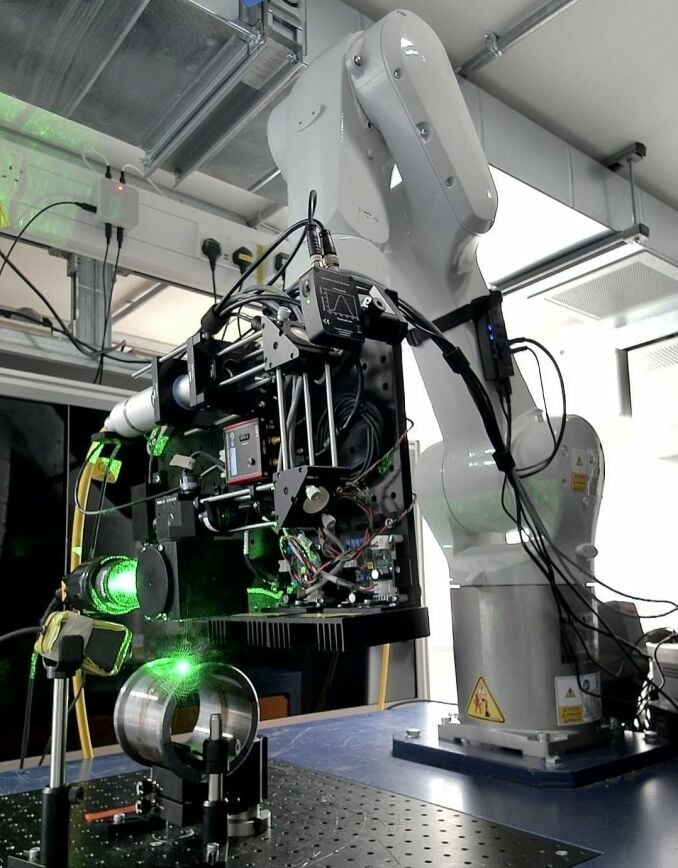

Robo-LIPA, a robotic system owned by the University of Strathclyde, which is used to scan a pipe for defects using lasers

Recently a jointly organised UKAEA and Research Centre in Non-Destructive Evaluation (RCNDE) fusion event was hosted at the Culham Campus for the first time.

NDE is a technique used to inspect materials, components, or structures without causing damage. Traditionally, it employs methods such as ultrasound, x-ray, and thermal imaging to assess integrity, quality, and performance. NDE enables the early detection of flaws or weaknesses in materials, ensuring components are defect free and structurally sound. In environments like fusion, where safety and reliability are paramount, NDE plays a crucial role in maintaining the integrity and performance of tokamaks, keeping humans out of harmful environments.

Laser Induced Phased Array (LIPA) is an advanced NDE technique, recently trialled in a collaboration between RACE and the University of Strathclyde, to inspect a weld defect on the inner surface of a pipe. The image below was taken during the trial, showing the generation (red) and defection (green) laser beams impinged on the outer surface of the pipe.

The NDE event at Culham was filled with insightful presentations that highlighted the unique challenges of fusion followed by the latest developments in NDE as possible solutions.

Robo-LIPA, a robotic system owned by the University of Strathclyde, which is used to scan a pipe for defects using lasers

Morning Session: Leaders from UKAEA, Tokamak Energy, and Commonwealth Fusion Systems outlined the current challenges faced in the fusion sector, setting the stage for a productive dialogue.

Midday Workshop: Facilitated by RCNDE, this session dived into capturing and prioritising the NDE requirements for fusion, enhancing a collective understanding and setting the research priorities.

Afternoon Insights: We heard from the University of Liverpool, University of Strathclyde, University of Bristol/Inductosense, Imperial College of London and Full Matrix Ltd. Topics ranged from real-time condition monitoring and laser ultrasonic inspections methods to innovative approaches like WAND-Light for remote sensor integration and future NDE solutions for fusion.

The feedback was overwhelmingly positive, reinforcing the need for ongoing collaboration. As the fusion sector evolves, these discussions are critical to developing reliable and standardised NDE practices to meet the demands of this challenging field.

Recently, UKAEA’s Manufacturing Technology and Equipment Qualification (MTEQ) Group hosted a pivotal event at Culham focusing on Non-Destructive Evaluation (NDE) for fusion, bringing together experts across the field.

NDE is a technique used to inspect materials, components, or structures without causing damage. Traditionally, it employs methods such as ultrasound, x-ray, and thermal imaging to assess integrity, quality, and performance. NDE enables the early detection of flaws or weaknesses in materials, ensuring components are defect free and structurally sound. In environments like fusion, where safety and reliability are paramount, NDE plays a crucial role in maintaining the integrity and performance of tokamaks, keeping humans out of harmful environments.

Laser Induced Phased Array (LIPA) is an advanced NDE technique, recently trialled in a collaboration between RACE and the University of Strathclyde, to inspect a weld defect on the inner surface of a pipe. The image below was taken during the trial, showing the generation (red) and defection (green) laser beams impinged on the outer surface of the pipe.

The NDE event at Culham was filled with insightful presentations that highlighted the unique challenges of fusion followed by the latest developments in NDE as possible solutions.