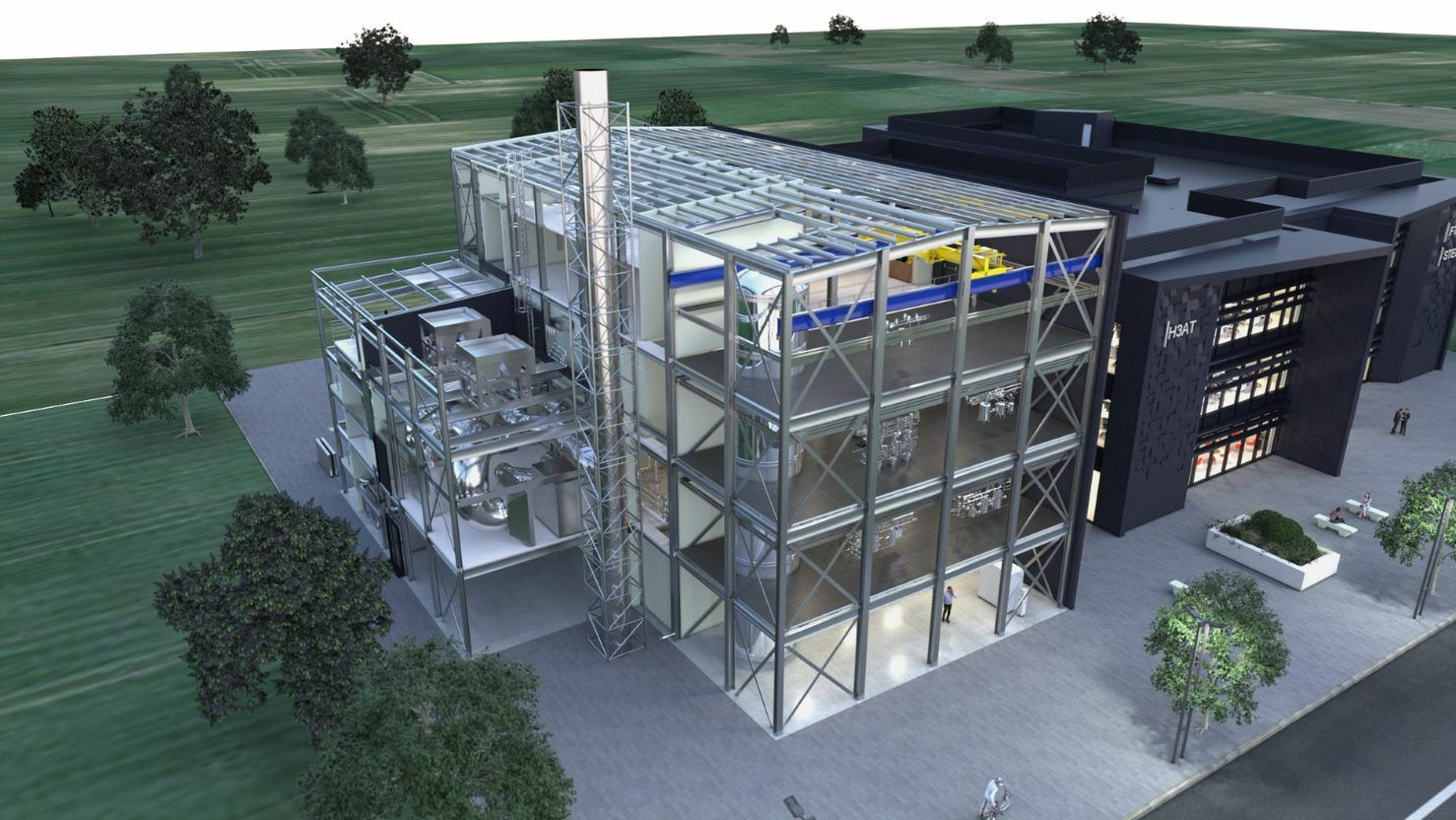

Artist impression of the H3AT Facility at Culham Campus (Copyright United Kingdom Atomic Energy Authority)

Artist impression of the H3AT Facility at UKAEA’s Culham Campus (Copyright United Kingdom Atomic Energy Authority)

About AtkinsRéalis

Created by the integration of long-standing organisations dating back to 1911, AtkinsRéalis is a world-leading professional services and project management company dedicated to engineering a better future for our planet and its people. We create sustainable solutions that connect people, data and technology to transform the world's infrastructure and energy systems. We deploy global capabilities locally to our clients and deliver unique end-to-end services across the whole life cycle of an asset including consulting, advisory & environmental services, intelligent networks & cybersecurity, design & engineering, procurement, project & construction management, operations & maintenance, decommissioning and capital. The breadth and depth of our capabilities are delivered to clients in strategic sectors such as Engineering Services, Nuclear and Capital. News and information are available at www.atkinsrealis.com.

AtkinsRéalis has been appointed by UK Atomic Energy Authority (UKAEA) to deliver the detailed design of a world-first Isotope Separation System to strengthen research into sustainable fusion delivery.

The Isotype Separation System will form part of UKAEA’s Hydrogen-3 Advanced Technology (H3AT) Facility, a world-first tritium fuel cycle research facility to include a prototype-scale process plant and experimental platform, which is a scaled version of the design for ITER. The tritium capacity of this highly complex Isotope Separation System will make it the most advanced research facility of its kind, helping to enable the development of tritium fuel cycle infrastructure necessary for sustainable fusion power.

AtkinsRéalis has already completed the concept and detailed process design of the main H3AT facility, currently under construction at UKAEA’s Culham Campus, in Oxfordshire, alongside the concept and preliminary design of the Isotype Separation System. The AtkinsRéalis team will now deliver detailed process and mechanical designs for the system, including the vital cryogenic and ambient temperature equipment that will be required to collect, process, and recycle the tritium fuel.

Jason Dreisbach, Head of Advanced Energy Technologies at AtkinsRéalis, said:

“The H3AT facility will be a first-of-a-kind research facility to strengthen UK and international efforts to advance tritium fuel cycle technology. The Isotype Separation System is a key element to demonstrate fusion fuel cycle performance at scale, and we look forward to contributing our significant experience in fusion engineering and tritium to help realise UKAEA’s ambitions.”

Stephen Wheeler, UKAEA Executive Director, said:

“UKAEA’s H3AT facility is an important milestone in the development of tritium technology.

“We are pleased to continue our partnership with AtkinsRéalis to deliver the Isotope Separation System at the H3AT Facility.

“This system will be the first industrial-scale tritium facility for fusion in the world and will enable industry and academia to study how to process, store and recycle tritium, a key fusion fuel.

“Fusion energy has great potential, not only as a source of abundant, low-carbon energy, but as a driver of economic activity for UK industry.

“By partnering with organisations like AtkinsRéalis, UKAEA is developing industrial fusion capability, which will enable the UK to become a global exporter of fusion technology.”

AtkinsRéalis will incorporate the use of the latest digital technology, including 4D design, digital twinning and AR/VR simulation to optimise delivery and help researchers and academia to better understand the design and performance of the system. The appointment builds on the firm’s international fusion expertise: in the UK an AtkinsRéalis-led consortium was appointed Engineering Delivery Partner for phase one of the UKAEA’s Spherical Tokamak for Energy Production (STEP) programme, alongside AtkinsRéalis’ existing roles on the STEP programme as Power Infrastructure Partner, Commercial Pathways Partner, and Site Selection & Development Partner. AtkinsRéalis was also appointed to the U.S. Department of Energy’s Princeton Plasma Physics Laboratory’s fusion programme in a multi-disciplinary engineering consortium and has also supported the international fusion facility ITER since 2010 as Architect Engineer through the Engage consortium.

Artist impression of the H3AT Facility at Culham Campus (Copyright United Kingdom Atomic Energy Authority)

AtkinsRéalis has been appointed by UK Atomic Energy Authority (UKAEA) to deliver the detailed design of a world-first Isotope Separation System to strengthen research into sustainable fusion delivery.

The Isotype Separation System will form part of UKAEA’s Hydrogen-3 Advanced Technology (H3AT) Facility, a world-first tritium fuel cycle research facility to include a prototype-scale process plant and experimental platform, which is a scaled version of the design for ITER. The tritium capacity of this highly complex Isotope Separation System will make it the most advanced research facility of its kind, helping to enable the development of tritium fuel cycle infrastructure necessary for sustainable fusion power.

AtkinsRéalis has already completed the concept and detailed process design of the main H3AT facility, currently under construction at UKAEA’s Culham Campus, in Oxfordshire, alongside the concept and preliminary design of the Isotype Separation System. The AtkinsRéalis team will now deliver detailed process and mechanical designs for the system, including the vital cryogenic- and ambient temperature equipment that will be required to collect, process, and recycle the tritium fuel.

Jason Dreisbach, Head of Advanced Energy Technologies at AtkinsRéalis, said: “The H3AT Facility will be a first-of-a-kind research facility to strengthen UK and international efforts to advance tritium fuel cycle technology. The Isotype Separation System is a key element to demonstrate fusion fuel cycle performance at scale, and we look forward to contributing our significant experience in fusion engineering and tritium to help realise UKAEA’s ambitions.”

Stephen Wheeler, UKAEA Executive Director, said: “UKAEA’s H3AT facility is an important milestone in the development of tritium technology.

“We are pleased to continue our partnership with AtkinsRéalis to deliver the Isotope Separation System at the H3AT Facility.

“This system will be the first industrial-scale tritium facility for fusion in the world and will enable industry and academia to study how to process, store and recycle tritium, a key fusion fuel.

“Fusion energy has great potential, not only as a source of abundant, low-carbon energy, but as a driver of economic activity for UK industry.

“By partnering with organisations like AtkinsRéalis, UKAEA is developing industrial fusion capability, which will enable the UK to become a global exporter of fusion technology.”

AtkinsRéalis will incorporate the use of the latest digital technology, including 4D design, digital twinning and AR/VR simulation to optimise delivery and help researchers and academia to better understand the design and performance of the system. The appointment builds on the firm’s international fusion expertise: in the UK an AtkinsRéalis-led consortium was appointed Engineering Delivery Partner for phase one of the UKAEA’s Spherical Tokamak for Energy Production (STEP) programme, alongside AtkinsRéalis’ existing roles on the STEP programme as Power Infrastructure Partner, Commercial Pathways Partner, and Site Selection & Development Partner. AtkinsRéalis was also appointed to theU.S. Department of Energy’s Princeton Plasma Physics Laboratory’s fusion programme in a multi-disciplinary engineering consortium and has also supported the international fusion facility ITER since 2010 as Architect Engineer through the Engage consortium.